printing process -尊龙凯时网娱乐官网

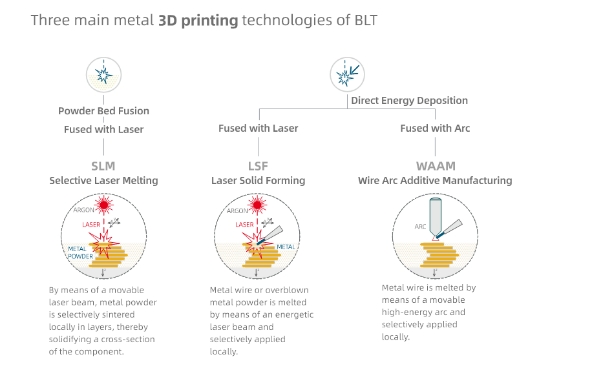

selective laser melting (slm):

selective laser melting (slm) is a metal additive manufacturing (am) technology that uses a bed of powder with a source of heat to create metal parts.

laser solid forming (lsf):

laser solid forming (lsf) is a typical laser direct energy deposition additive manufacturing technology based on the powder feeding method with a high deposition rate.

wire arc additive manufacturing (waam):

wire arc additive manufacturing (waam) is a wire-based ded approach that uses an electrical arc as a source of fusion to melt the wire feedstock and deposit a part preform, layer by layer.

the blt intelligent manufacturing factory is equipped with 380 sets of machines and systems, with nearly half of them being large-format systems. the build dimensions of the large-format systems range from 400mm to 1500mm, while the build dimensions of the small and medium-format machines and systems range from 160mm to 400mm. machines and systems of all sizes are capable of meeting the manufacturing requirements for various aerospace parts.