blt-尊龙凯时网娱乐官网

optimized upgrade solutions, reduce costs and increase efficiency

-

laser fda safety registration

-

iso9001:2015 / iso14001:2015 / iso45001:2018

-

supporting materials

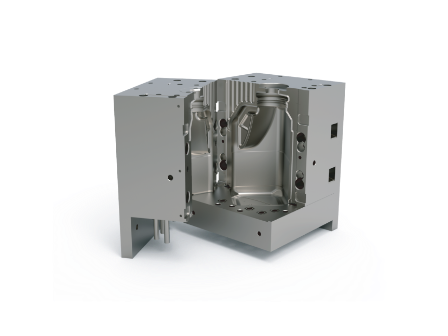

titanium alloy, aluminum alloy, superalloy, stainless steel, high-strength steel, tool steel -

build dimension(1)

450mm×450mm×500mm(w×d×h) -

laser power

500w×4;500w×6;500w×8 -

building speed(2)

100cm³/h; 150cm³/h; 200cm³/h

application fields

-

aviation

-

aerospace

-

automotive

-

engine

(1)excluding substrate thickness.

(2)dependent on part geometry, material and parameter set used.

*the displayed products are provided for reference purposes only.

* the actual models available may vary according to the product listings in each specific region.

(2)dependent on part geometry, material and parameter set used.

*the displayed products are provided for reference purposes only.

* the actual models available may vary according to the product listings in each specific region.

advantages

-

mass application validation

iterative optimization of mature product

solution is constantly evolving -

multi-laser efficient forming

a variety of laser quantities are available

efficient and dynamic recoating in double directions -

self-adapting powder spreading correction

deep learning technology

automatic detection and correction of powder deficiency -

long-life filtration system

automatic backblow cleaning

long-life filter ensures continuous use -

automatic circulation of powder

powder closed-circulation processing system

automatic recycling sieving and supply -

safe and economical production

save gas and powder to enhance economical

inert gas protection makes powder collection safer

related cases

1/1

intelligent modules help you

achieve more

standard functions

- diagnosis fault-grading

- process data traceability

- recoating detection

optional functions

- automatic grafting

- 3d reconstruction

- blt-mcs connect