printing process -尊龙凯时网娱乐官网

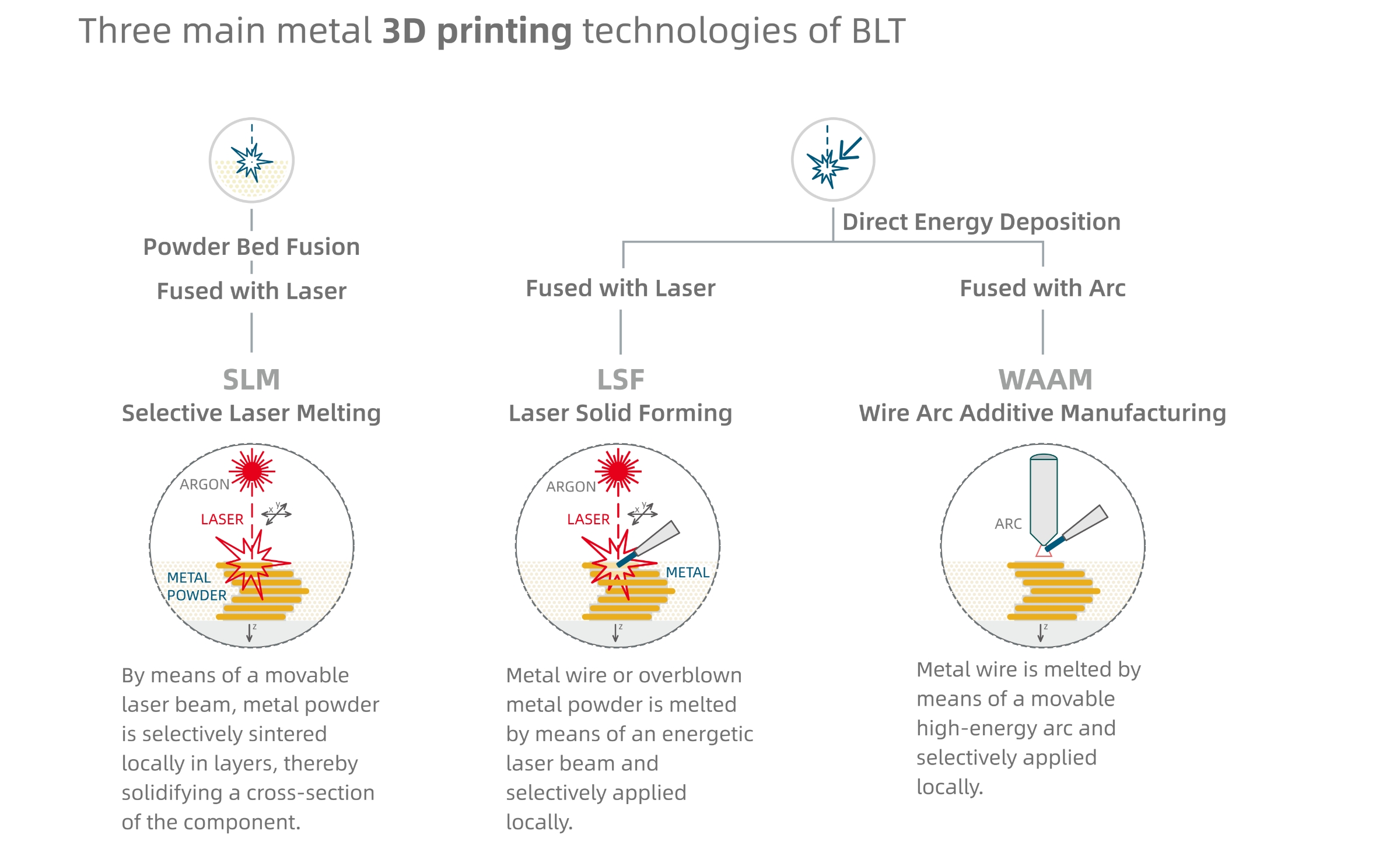

selective laser melting (slm):

selective laser melting (slm) is a metal additive manufacturing (am) technology that uses a bed of powder with a source of heat to create metal parts.

laser solid forming (lsf):

laser solid forming (lsf) is a typical laser direct energy deposition additive manufacturing technology based on the powder feeding method with a high deposition rate.

wire arc additive manufacturing (waam):

wire arc additive manufacturing (waam) is a wire-based ded approach that uses an electrical arc as a source of fusion to melt the wire feedstock and deposit a part preform, layer by layer.

blt intelligent manufacturing factory has 380 sets of machines & systems, of which nearly half are large-format systems. the build dimension of large-format system is from 400mm to 1500mm, and the build dimension of small and medium-format machines & systems is from 160mm to 400mm. machines & systems of all sizes meets the forming needs of various parts in aerospace.

| material categories | materials | forming technology | rm/mpa | rp0.2 /mpa | a/% |

| titanium alloy | ti-6al-4v grade5 |

slm | 960-1100 | 900-960 | 12.0-19.5 |

| forging | 895 | 825 | 10.0 | ||

| ti-6.5al-1mo-1v-2zr | slm | 1030-1130 | 950-1050 | 13.5-18.0 | |

| forging | 930-1130 | 855 | 10.0 | ||

| tiam1 | slm | 950-1000 | 880-930 | 12.0-18.0 | |

| forging | / | / | / | ||

| aluminum alloy | alsi10mg | slm | 290-320 | 190-205 | 12.0-18.5 |

| casting | 235 | / | 2.0 | ||

| alsi7mg | slm | 420-450 | 270-300 | 4.0-10.0 | |

| casting | 235 | / | 4.0 | ||

| superalloy | in718 | slm | 1400-1500 | 1200-1300 | 15.0-20.0 |

| forging | 1280 | 1030 | 12.0 | ||

| in625 | slm | 870-980 | 430-550 | 40.0-60.0 | |

| forging | 830 | 410 | 30.0 | ||

| hastelloyx | slm | 700-740 | 300-320 | 45.0-55.0 | |

| forging | 690 | 275 | 30.0 | ||

| k452 | slm | 1100-1300 | 790-850 | 5.5-15.0 | |

| forging | 830 | 715 | 4.1 | ||

| stainless steel | 304l | slm | 550-670 | 350-390 | 53.5-75.5 |

| forging | 520 | 205 | 40.0 | ||

| 316l | slm | 605-710 | 385-445 | 45.0-68.0 | |

| forging | 480 | 177 | 40.0 | ||

| 15-5ph | slm | 1418-1434 | 1250-1300 | 10.0-15.0 | |

| forging | 1310 | 1170 | 10.0 | ||

| 17-4ph | slm | 1150-1250 | 980-1050 | 10.0-18.0 | |

| forging | 1070 | 1000 | 12.0 |